It's a timber frame house with a small footprint and lots of usable space. It utilizes southern exposure, super insulation and wood heat. I feel strongly about creating buildings that enrich the lives of the inhabitants on a realistic budget. This house will put our ideals about what that means into practice.

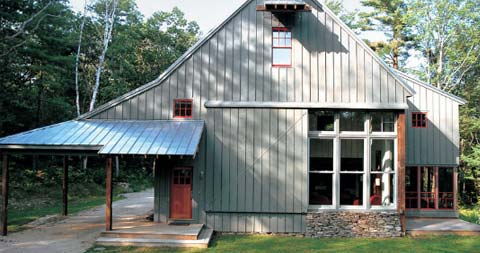

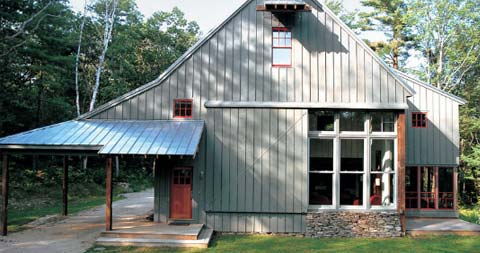

Since timber frames are load bearing structures in themselves, there are many options for insulation beyond 2x walls with fiberglass or foam between the studs. Ideally you utilize a system that doesn’t involve the redundancy of another load bearing wall attached to the timber frame. We often install panels on timber frames we build, but wanted to explore other methods in our own house. Our plan was to build double stud walls and then blow in cellulose for insulation. This would allow us to use a recycled product to create a wall with a high r-value. Building our own insulation system would also mean using our labor, rather than paying the panel company to pre-build and cut the panels. In the end however, it seemed like we might never have walls if we didn’t go the panel route—so that is what we did and thirteen days after the panels arrived we had a weather tight structure. It is still a thrill for me to pull in the driveway and see a building with windows, but I imagine it is only a matter of time before the beauty of black felt paper and orange cap nails wears thin and I yearn for siding and a porch.

In planning this house, I spent many hours working on making the spaces flow together and on determining the size and location of the windows. I have not thought very much along the way about the lighting that will go into those spaces.

In planning this house, I spent many hours working on making the spaces flow together and on determining the size and location of the windows. I have not thought very much along the way about the lighting that will go into those spaces. then drilled up through the roof panels and spaces for electrical boxes chiseled out of the roof decking. Before we could do the final step to get the roof weather tight we ran wires over the roof panels for every ceiling light that will hang from the roof. In this house it was the lights in the bedrooms and in the entry and stair areas.

then drilled up through the roof panels and spaces for electrical boxes chiseled out of the roof decking. Before we could do the final step to get the roof weather tight we ran wires over the roof panels for every ceiling light that will hang from the roof. In this house it was the lights in the bedrooms and in the entry and stair areas.